Description

| SH 10 Ecoline | SH 10 | SH 10 XL Ecoline | SH 10 XL | |

|---|---|---|---|---|

| Crimp force (kN/Ton) | 2,800/280 | 2,800/280 | 2,800/280 | 2,800/280 |

| No grease 20% less friction | ✓ | ✓ | ✓ | ✓ |

| Control | Control A | Control A | Control A | Control A |

| SAE R 15/4SH* 1 piece fitting | 2″ | 2″ | 2″ | 2″ |

| 4SH* 2 piece fitting | 2″ | 2″ | 2″ | 2″ |

| SAE R 15* 2 piece fitting | 2″ | 2″ | 2″ | 2″ |

| Industrial | 4″ | 4″ | 4″ | 4″ |

| 90° Elbows | 2″ | 2″ | 2″ | 2″ |

| Crimp range (mm/inch) | 145 / 5.70 | 145 / 5.70 | 145 / 5.70 | 145 / 5.70 |

| Opening (mm/inch) | +45 / +1.77 | +45 / +1.77 | +61 / +2.40 | +43 / +1.69+61 / +2.40 |

| Opening without dies (mm/inch) | 190 / 7.48 | 190 / 7.48 | 200 / 7.87 | 200 / 7.87 |

| Master dies length (mm/inch) | 126 / 4.96 | 126 / 4.96 | 126 / 4.96 | 126 / 4.96 |

| Types of dies | 239 – xx/237 L ** | 239 – xx/237 L ** | 239 – xx0/237 L ** | 239 – xx0/237 L ** |

| Speed (mm/sec) | 30/4.9 1.4 30/8.6 | 30/4.9 1.4 30/8.6 | ||

| Close | 70 dBA | 67 dBA | ||

| Crimp | 5.5 kW 3 VAC | 5.5 kW 3 VAC | ||

| Open | 85 L | |||

| 4.8 | 690 x 750 x 1,470 | 690 x 750 x 1,470 | ||

| 2.3 | 553 kg | 555 kg | ||

| 7.9 | ||||

| ✓ | – | |||

| 6.1 | ✓ | – | ||

| 1.7 | ✓ | ✓ | ||

| 10.3 | ||||

| 30/6.0 | ||||

| 1.4 | ||||

| 30/17 | ||||

| 30/6.0 | ||||

| 1.4 | ||||

| 30/17 | ||||

| Noise level | 70 dBA | 67 dBA | 67 dBA | 70 dBA |

| Drive | 4 kW 3 VAC | 5.5 kW 3 VAC | 4 kW 3 VAC | 5.5 kW 3 VAC |

| Oil | 70 l | 70 l | 70 l | 70 l |

| L x W x H (mm) | 700 x 600 x 845 | 690 x 600 x 1,400 | 700 x 600 x 845 | 690 x 600 x 1,400 |

| Weight | 372 kg | 390 kg | 390 kg | 430 kg |

| Options | ||||

| 12 VDC/24 VDC | ✓ | – | ✓ | – |

| 1 Phase | ✓ | ✓ | ✓ | ✓ |

| Control C.2/IPC | ✓ | ✓ | ✓ | ✓ |

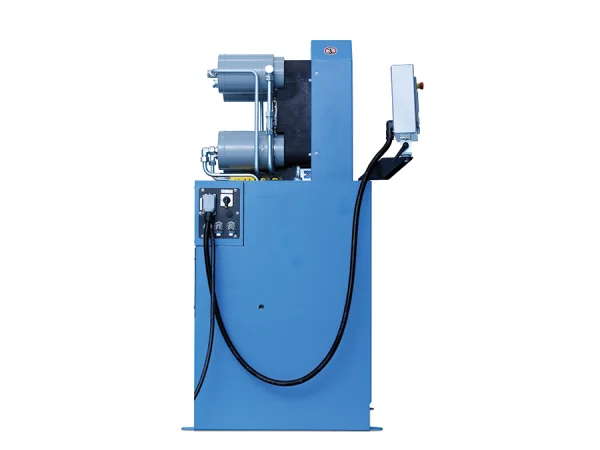

With a 370-ton crimping force, the new SC 12 i is the most powerful workshop crimper for R15 industrial hoses up to 3“ and high pressure hoses up to 1“. With its large opening and a maximum crimping range of up to 139 mm (5.47“), the SC 12 i also crimps 4“ Camlock industrial fittings and even 90° fittings with ease.

Large opening travel

- Easy pressing of elbow fittings without removing the pressing dies

Large pressing tool

- Also allows crimping of up to 4 inch industrial hoses

Compact design

- Finds place in any workshop

Plain bearing technology

- Lubricant-free – for more cleanliness and longer machine life

- Maximum productivity, with extremely low operating costs

- No contamination of the hose line with grease

- Ideal also for the food and pharmaceutical industry

- Reduces press force loss by up to 20%

- Consistent accurate crimp force

Ecoline version

- Entry level model with the same quality